What You Need to Know About CNC Technology Today

Machining has come a long way over the past decades, but in most instances, the core process remains very much the same. You are cutting and shaping a piece of metal to transform it from its raw form into something more conducive to a specific use case. However, while the fundamentals remain the same, the underlying tech has moved forward in leaps and bounds, which is what we will explore in this post. From the use of advanced software and robotics to ensure a high level of productivity and reduced waste to the fact that the precision of the end products is now more precise than ever before, we will examine it all.

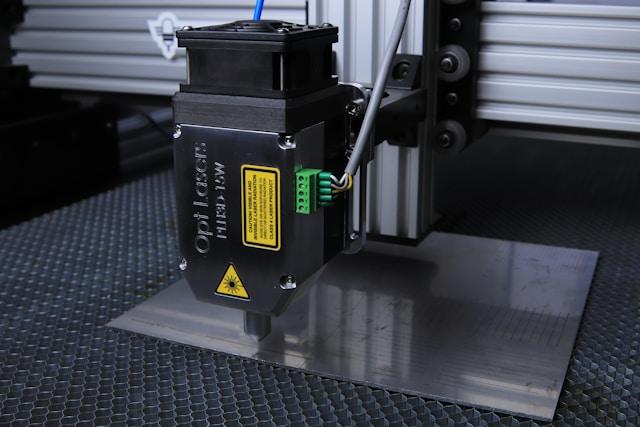

The Cutting Tools Are As Advanced As The Machines Themselves

While most of the focus on these kinds of industries and devices tends to lean more heavily toward the machines themselves, it is the bits and drill pieces that are often the unsung heroes that do most of the heavy lifting. Although CNC machining is a catchall term for many different techniques, they all share a common component: the bits. Because of the accuracy required for CNC manufacturing, the cutting tools need to be incredibly precise while also being durable enough to literally cut through metal!

Sophisticated Software Enables Ever More Precise Designs

Any time of machinery is essentially rendered moot if there are no designs for the operator to follow. This is where software comes into play, more specifically, CAD software. CAD, Computer-Aided Design, is used extensively in CNC manufacturing and enables engineers to create incredibly detailed designs in a 3D environment that the computer can follow as it goes through the process. As new technology like the seemingly ubiquitous AI becomes integrated into these platforms, we will begin to see ever more advanced designs being created that include highly detailed instructions that can be used in a variety of ways.

Robotics Reduces Waste And Increases Efficiency

It’s no great secret that robotics and automation have taken over the manufacturing industry, but this is typically for a good reason. While it’s never nice to see people lose their jobs to machines, the advantages they bestow upon a company are too good to overlook. When you allow a robot to machine your designs, you generate vast quantities of the final product very quickly while reducing the amount of waste produced in the process. There will never be any substitute for certain handcrafted products, that much is true, but when it comes to things that need to be mass-produced or crafted to such a high degree of accuracy that it is impossible for a human to create, only robotics paired with some form of automation is impossible to beat.

Constantly Connected Machines Can Feed Data To Managers

When you are able to connect a CNC to a network, you can gain some pretty unique insights that can help you to manage the process more effectively, as well as inform you when bits need replacing or if productivity is dropping (which you can then use to figure out why). This can also all be performed remotely, keeping the shop floor clear and creating a far safer environment for all involved.

Most of the modern world has been built in some way or another with the help of CNC. It’s also incredible to see how different technologies are being integrated and where this will lead the industry in the future.