Thin Film Deposition Techniques: A Diverse Exploration

Thin films, despite their slim profile, play a significant role across various industries. They're the unsung heroes behind the screens of our devices, the efficiency of our solar panels, and the precision of our microelectronics. In this blog, we'll delve into the fascinating world of thin film deposition techniques, unravelling their importance and diversity.

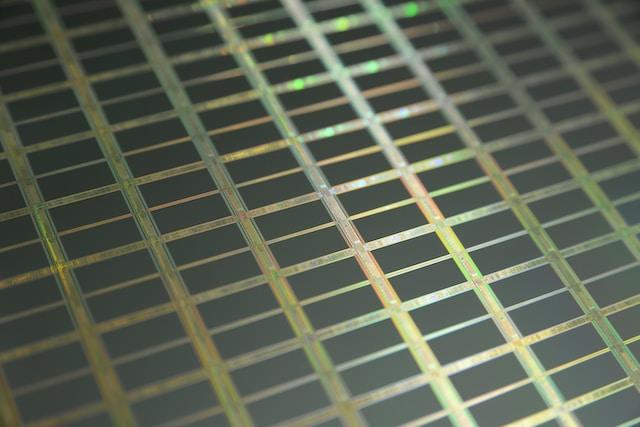

The Fundamentals of Thin Films

Thin films, as the name suggests, are exceedingly thin layers of material, often just a few atoms thick. They are applied to substrates to enhance their properties or create entirely new functionalities. These films are vital in industries ranging from electronics to optics, where even a tiny thickness variation can impact performance. You can learn more about this topic by checking this article by Korvus Technology.

Why Thin Film Deposition Matters

Thin film deposition isn't just some obscure procedure; it's a fundamental cornerstone of modern technology. These super-thin layers play a crucial role in how many of our everyday gadgets and gizmos work. So, let's dive into why they're such a big deal in a variety of fields.

Classification of Thin Film Deposition Techniques

Physical Vapour Deposition (PVD)

Imagine painting, but instead of using a brush and paint, you're working with individual atoms. That's what Physical Vapour Deposition (PVD) is all about. It's a fascinating process that takes a solid material and turns it into a vapour. This vapour then magically reappears on a substrate, creating a super thin film.

Chemical Vapour Deposition (CVD)

Chemical Vapour Deposition (CVD) is a fascinating process that uses chemical reactions to create thin films on various surfaces. It's a versatile technique and has variations like PECVD and LPCVD. This method finds its applications in a wide range of fields, including semiconductor manufacturing and coatings. It's a crucial technology in these industries, helping to achieve precise and high-quality results.

Atomic Layer Deposition (ALD)

Atomic Layer Deposition (ALD) is all about taking things one tiny step at a time. It's not flashy or over-the-top, but it's exact, and that's what makes it perfect for the world of nanotechnology and photovoltaics. What sets ALD apart is its unique ability to carefully build up layers, atom by atom, offering unmatched control in the deposition process.

Sol-Gel Deposition

Sol-gel deposition is an excellent technique where we make thin films from a liquid precursor. It's super versatile, and you can use it for all sorts of things, especially in the fields of optics and sensors. What's excellent about Sol-Gel is that it's a cost-effective and straightforward way to create these thin films, making it a practical choice compared to some of the more complex methods out there.

Spin Coating and Dip Coating

Spin coating and dip coating may not be the flashiest methods out there, but they're excellent when it comes to making thin films. Think of them as the unsung heroes of the photovoltaics and display world. These techniques basically involve either spinning the substrate or dipping it into a solution to get that perfect thin coating. So, while they might not steal the spotlight, they sure do get the job done straightforwardly and effectively.

Factors Influencing Thin Film Deposition

Substrate Selection

Picking a suitable substrate is a big deal. It's like the foundation for a building; if it's not solid, the whole structure can crumble. When it comes to films, the material you choose as the base can significantly affect how the final product turns out. It's not a one-size-fits-all situation because different uses require different materials to shine. So, taking the time to select the correct substrate is critical to getting the results you want.

Temperature and Pressure Control

Maintaining precise control over temperature and pressure during the deposition process is absolutely crucial. These two variables determine the thickness and uniformity of the film, and they can either make or break the entire operation.

Film Growth Mechanisms

It's essential to grasp the ways in which films grow, as this knowledge plays a crucial role in determining the result. These growth mechanisms shape the structure and characteristics of the film. By mastering these mechanisms, you gain the ability to tailor the movie to meet specific goals.

Emerging Trends in Thin Film Deposition

Let's explore the dynamic world of thin film deposition, where recent advancements are shaping industries with innovative trends and breakthroughs:

Nanotechnology Integration

Thin film deposition is teaming up with nanotechnology to create super-small materials and coatings. This precise technique is crucial for making nanostructured materials used in electronics, sensors, and medical devices, and they have some fantastic properties that are changing how we work with matter at atomic and molecular levels.

Thin Film Batteries

Thin film batteries are transforming energy storage. These ultra-thin, flexible power sources offer higher energy density, faster charging, and improved flexibility compared to traditional lithium-ion batteries. Thin film deposition techniques are critical to their production, paving the way for innovation in the electronics industry.

Sustainable Materials

In the world of technology, sustainability is gaining ground. Researchers and engineers are now using eco-friendly materials like biodegradable polymers and organic compounds in thin film production. It not only reduces environmental impact but also aligns with global efforts to cut down on waste and energy use while maintaining high-performance materials.

Challenges and Future Prospects

Thin film deposition has come a long way, but there are some hurdles we need to clear before we can fully tap into its potential. These challenges span various technology areas and their practical applications.

Scalability

Scaling up deposition techniques for larger substrates without compromising quality is a crucial challenge in the thin film industry. Overcoming this issue is vital for expanding light film technology's use in areas like solar energy and flexible electronics.

Cost-Efficiency

Thin film deposition can be quite resource-intensive, and keeping costs in check is a big deal. The goal is to lower the price for each unit of area without compromising on quality. To achieve this, we need to focus on innovations in materials and process optimization. These innovations are crucial in order to make thin film technology more widely available and helpful across various applications and industries.

Conclusion

Thin film deposition techniques, despite their subtlety, are the driving force behind many technological marvels. Whether you're gazing at your smartphone screen, marvelling at a solar panel, or working on cutting-edge electronics, these films are there, quietly shaping our world. Understanding their diversity and significance opens the door to countless possibilities in innovation and industry.